The HVAC industry is familiar and far too comfortable with ducted ventilation. However, the traditional ducted ventilation system has its own drawbacks and is not the ideal solution for all your ventilation requirements. Newer ductless ventilation technology like iHVAC’s iJETFAN combined with our state-of-the-art control systems the iJETCON can overcome many of the problems of a traditional ducted ventilation system as explained below.

Ease of Installation

In a typical case where one prefers an old-school ducted ventilation system over ductless ventilation technology like the iJETFAN, vast amounts of money, time and resources are spent on designing, constructing and installing ductwork over the entire area in consideration.

By choosing a ductless ventilation solution like iJETFAN, builders and consultants can save on these costs by conducting a CFD analysis of the car park during the design phase and strategically placing iJETFANs to achieve improved efficiency and air change rate, thereby eliminating all the costs associated with ductwork running across the enclosed car park or any other similar areas where an iJETFAN can be a strategic and financial benefit over ducted ventilation system.

Reduced Site Excavation:

Due to the low height requirements when choosing a ductless ventilation system like iJETFAN over a traditional ducted design, excavation requirements in the underground car park are reduced compared to when selecting a traditional ducted ventilation solution. This eventually translates to reduced excavation costs by choosing a ductless ventilation solution, not to mention reduced construction materials like concrete, steel, etc., and associated labour costs.

Reduced Plenum Runs:

In an underground car park, a plenum chamber is a crucial component of the ducted ventilation system. It serves as a distribution point for fresh air and a collection point for exhaust air. Not only is this an added cost to the builder (construction, raw materials, labour, etc.,) but it also increases engineering and design manhours spent to achieve the required fresh air change rate to comply with Australian Standards.

When choosing a ductless ventilation solution like the iJETFAN, Plenum runs can be potentially reduced or eliminated altogether in the case of an open-sided car park. In either case, using an iJETFAN over traditional ducted ventilation means, one supply and one exhaust riser can be eliminated from the design of the underground car park. In other words, choosing iJETFAN over traditional ducted ventilation has cost benefits right from the design phase to the construction phase.

Easy Installation of other Building services:

On choosing a ductless ventilation system like iJETFAN over traditional ducted ventilation in a basement car park, due to the clear ceilings void of any ductwork, it becomes easier for installation and maintenance of other building services like electrical, plumbing, gas, water, cable trays, etc., can be easily installed without having to navigate around any ductwork on the ceilings, reducing the number of manhours and materials spent to get the job done.

Ease of Maintenance:

When you choose a ductless ventilation system over ducted ventilation, maintenance costs associated with cleaning the dampers and accessing them can be eliminated. There are no distribution ducts or dampers to be inspected and maintained and accessing an iJETFAN for scheduled maintenance is easy and overall maintenance expense is comparatively lesser than a ducted system.

Better CCTV coverage:

No ductwork in an underground car park with limited height restrictions means better CCTV coverage. In conjunction with our strategically placed iJETFANS in the basement car park, excellent CCTV coverage can be easily achieved for a safer environment for both drivers and pedestrians accessing the car park. Say goodbye to unpleasant ductwork blocking the camera angle views and extra hours spent installing cameras around the ductwork to achieve satisfactory CCTV coverage.

Low system resistance:

When designing and operating a ducted ventilation system, resistance to the airflow is a critical factor as it can impact the system’s performance, energy efficiency, and the amount of noise generated. This resistance is primarily due to factors such as friction, turbulence, and changes in direction within the ducts, as well as any obstacles or components (e.g., dampers, filters) that the air must pass through.

System resistance is a critical consideration in the design and operation of ventilation systems, as it can impact the system’s performance, energy efficiency, and the amount of noise generated. When air encounters resistance, the pressure within the ductwork drops, and the fan must work harder to maintain the desired airflow rate. This results in increased energy consumption and potentially reduced ventilation effectiveness.

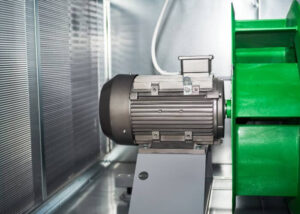

Ductless ventilation technology like iHVAC’s iJETFAN can eliminate all these issues and will require less powerful supply and exhaust fans, delivering better airflow rates, lesser noise pollution and higher system efficiency. This can also lead to utilising in-line axial fans mounted vertically rather than the traditional more expensive double inlet double-width centrifugal fans.

By conducting a thorough CFD modelling and strategically placing the iJETFANS, better airflow rates can be achieved, not to mention savings in energy costs and operating costs for the builder in the long run.

Reduced Plant room Size:

By choosing iHVAC’s ductless ventilation technology like the iJETFAN, we can reduce the size of the plant room or in some cases eliminate them completely by using natural supply or exhaust. Reducing the size of the plant room can have several benefits, including saving space, reducing installation costs, reducing noise pollution and improving overall system efficiency. The saved space can be better utilised for more car parking space and bicycle parking, hence giving a more pleasant and aesthetic look and feel to pedestrians and drivers accessing the car park.

As always, here at iHVAC, our engineering team conducts a thorough CFD analysis and presents multiple ventilation solutions to all our customers based on their requirements focusing on improving the overall system efficiency and reducing operating & energy costs in the long run. Speak to our engineering team today for a free consultation and quote your project.