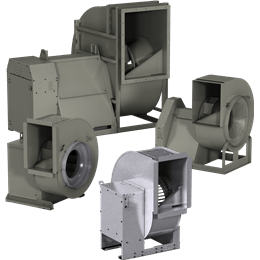

CENTRIFUGAL BLOWERS:

A centrifugal utility set or blower can be utilized in a wide selection of indoor or outdoor, supply or exhaust applications. These can be anything from commercial light to medium-duty general ventilation requirements to those requiring high airflows, manufacturing process, emergency, continuous high-temperature, or grease-laden exhaust. Units have many discharge configurations, which allow different airflow direction without system losses from duct turns. They are fabricated of steel with a wide range of corrosion resistant coatings. Housing designs offered are either lock-seam or fully welded construction. Choice of forward curved, backward inclined, or higher efficiency airfoil centrifugal wheels is available as standard. Options include aluminum or stainless steel wheels. Prior to shipment, each fan assembly is factory run and tested for quality assurance.

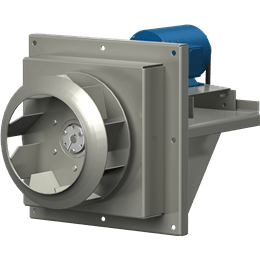

USF:

The USF has many construction configurations to choose from.

Galvanized Construction:

This is going to be the most economical fan available for its performance range. Constructed of heavy gauge galvanized steel, these fans are available in direct or belt drive arrangements.

Coated Steel Construction:

Coated steel material allows for the most configurations and a lower cost second to galvanized construction. This would be considered more of a standard fan offering with more options and accessories. These fans offer a corrosion-resistant coated finish and are suitable for spark resistant, restaurant grease exhaust, high temperature or general ventilation applications.

Aluminum Construction:

Aluminum fans are an excellent choice for moist or humid environments where there is concern about the fan’s exterior corroding. Aluminum is more costing than steel and doesn’t offer the same level of configurations or accessories as steel. Aluminum fans can either be mill-finish or coated.

Stainless Construction:

Stainless fans are the most expensive, but the only choice in applications requiring continuously high airstream temperatures. Stainless fans are mill finish and like aluminum and galvanized fans, have a more limited offering than coated steel fans.

The USF product has many types of wheels available in multiple grades of construction to meet the required level of performance.

- Forward-Curved (FC): Economical wheel. The forward-curved wheel has poor efficiency, but is low cost and quiet.

- Backward-Inclined (BI): Standard wheel. The backward-inclined wheel is a general-purpose type capable of performing most applications and available in multiple materials.

- Airfoil (AF): Premium wheel. The airfoil wheel offers a higher efficiency for reducing energy consumption.

The USF is designed to handle small to large volumes of air at low-to-high pressures in commercial and some industrial applications. These fans fit a broad range of fan applications such as hazardous environments, emergency smoke control, spark resistance, high volume/pressure capabilities, etc. Alternate construction materials are also available for corrosive or extreme high-temperature applications. Split housing also available for limited access installations.

- Arrangements 1, 4, 8, 10

- Up to 160,000 cfm

- Up to 21 in. wg

- Spark A, B or C resistant construction available

- Alternate material construction: Aluminum and Stainless steel

Certifications:

- UL/cUL Listed for Electrical (UL/cUL-705), Grease Exhaust (UL/cUL-762) and Power Ventilators for Smoke Control

- AMCA licensed for FEI, Air & Sound Performance

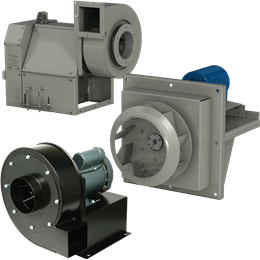

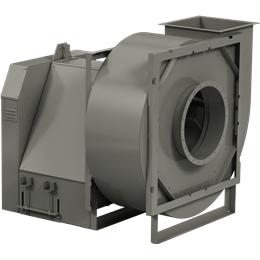

CENTRIFUGAL INDUSTRIAL FANS:

Applications for industrial blowers include high airflow volumes, manufacturing process exhaust, grease-laden, and emergency or continuous high-temperature exhaust. Prior to shipment, each fan assembly is factory run and tested to meet acceptable vibration criteria. A wide range of protective coatings is available. Construction is aluminum or stainless steel (airstream only). Backward-inclined or higher efficiency airfoil centrifugal wheels are available with heavy-gauge steel, fully welded or lock-seam housing.

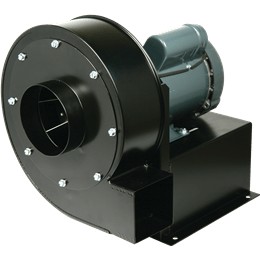

FPB: Model FPB is a pressure blower that uses a radial aluminum blade wheel providing efficient operation and spark resistant construction. Housing design is fully rotatable and constructed of steel with a baked polyester coating. All models are direct drive, arrangement 4 with wheels directly connected to the motor shaft.

IP: Greenheck industrial process fans are engineered and built for reliable operation in severe environments where high temperatures and static pressures, and material handling requirements are encountered. Model IP uses three different wheel designs and four construction levels to meet specific industrial requirements.

Wheel Types:

- Air handling – clean and light material-laden air

- Open radial – abrasive dust like grinding and buffing wheel exhaust, fume exhaust, and to convey granular materials, sawdust or wood chips

- Back plated/wool – long, fibrous and stringy material such as wood shavings, yarn or paper trimmings

- 200 to 143,000 cfm

- Up to 32 in. wg

- Spark A and B resistant construction available

Certifications: AMCA licensed for FEI & Air Performance

PLG

In most instances, plug fans are unhoused and rely on the plenum space around the backward-inclined centrifugal wheel to direct airflow as required in the system. Model PLG is available in belt or direct drive with steel, aluminum or 316 stainless steel constructions.

- 900 to 71,000 cfm per fan

- Up to 8 in. wg

- AMCA Spark B or C resistant construction (available)

- 800°F maximum operating temperature (optional)

FIBERGLASS REINFORCED PLASTIC BLOWERS:

Fiberglass reinforced plastic (FRP) centrifugal fans provide reliable and efficient operation in corrosive air movement applications. These fans can operate in a broad range of applications, however the typical use is in ducted systems. FRP fans can also be supplied with options for use in environments where a need for spark resistant construction exists.

BCSW-FRP:

Model BCSW-FRP is a single width FRP centrifugal blower that includes a backward-curved wheel and features a controlled laminate construction with a layer of ‘C’ veil as standard. This complies with ASTM D4167 and ASTM C582 specifications. The unit is available in belt or direct drive versions. Additional layers of corrosion resistant cloth and graphite impregnated liner for spark resistance are available options.

- 100 to 170,000 cfm per fan

- Up to 16 in. wg

- AMCA Spark A resistant construction

Certifications: AMCA licensed for FEI & Air Performance