HIGH PLUME LABORATORY EXHAUST FANS:

Vektor® fans with high-velocity discharge nozzles have multiple nozzle sizes available for each fan. These provide options in plume height, sound levels and energy consumption requirements, for any lab project application. These fans are cost-effective solutions compared to the field built-up fan and stack assemblies.

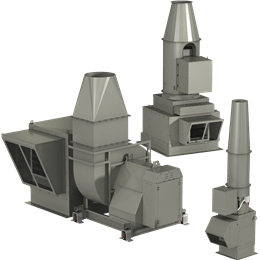

VEKTOR-H: The Vektor-H utilizes a direct or belt-driven, tubular centrifugal fan with an efficient conical nozzle designed to propel fumes safely away from the building. These fans can be configured in single, double or triple fan systems.

Certifications:

- Florida Building Code

- Florida Product Approval

- Notice Of Acceptance (NOA High Wind)

- Texas Department of Insurance

- UL/cUL Listed for Electrical (UL/cUL 705) and Grease Exhaust (UL/cUL 762)

- AMCA licensed for FEI, Air & Sound Performance

- HCAI Seismic Certified

VEKTOR-CH: The Vektor-CH uses a high-efficiency centrifugal wheel with backward-inclined flat or airfoil blade technology in a scroll style fan with an engineered high plume discharge nozzle. This centrifugal fan design offers greater airflow and pressure capabilities. The Vektor-CH is available in belt or direct drive arrangements and single fan to quadruple fan system configurations.

Certifications:

- UL/cUL Listed for Electrical (UL/cUL 705)

- AMCA licensed for FEI, Air & Sound Performance

- HCAI Seismic Certified

VEKTOR-MH: The Vektor-MH utilizes an inline, efficient mixed flow fan and conical nozzle, maximizing effective plume height. The Vektor-MH is available in belt or direct drive arrangements. The unit has a bifurcated housing, allowing safe, easy access to all drive components. There are several configurations with up to six fans on a single plenum.

Certifications:

- UL/cUL Listed for Electrical (UL/cUL 705)

- AMCA licensed for FEI, Air & Sound Performance

HIGH PLUME DILUTION LABORATORY EXHAUST FANS:

The high plume nozzle and dilution windband entrain outside ambient air to assist in the increased dilution of laboratory exhaust while maintaining effective plume height. Higher nozzle velocity creates a higher dilution, diluting and dispersing potentially hazardous exhaust or fumes quickly and safely.

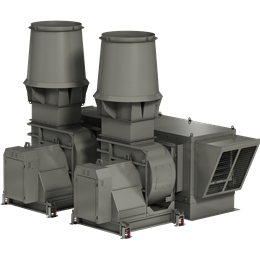

VEKTOR-CD: Vektor-CD utilizes a centrifugal blower with a backward-inclined flat or airfoil bladed wheel, making it ideal for systems requiring horizontal exhaust duct runs or having higher system pressures. There are three configuration options for belt or direct drive models. These are single, multiple parallel or opposed fan systems using up to four fans with a common plenum.

Certifications:

- UL/cUL Listed for Electrical (UL/cUL 705)

- AMCA licensed for FEI, Air, Sound and Induced Flow Performance

VEKTOR-MD: Vektor-MD utilizes an inline mixed flow fan available in belt or direct drive configuration both with a bifurcated housing, keeping drive components out of the contaminated airstream. The windband and nozzle combination entrain ambient air to assist in the dilution of the contaminated exhaust. Available with up to six fans on a common plenum, the Vektor-MD fan(s) can also be supplied with the Vektor-ERS, energy recovery system.

Certifications:

- UL/cUL Listed for Electrical (UL/cUL 705)

- AMCA licensed for FEI, Air, Sound and Induced Flow Performance

VARIABLE GEOMETRY NOZZLE LABORATORY EXHAUST FANS:

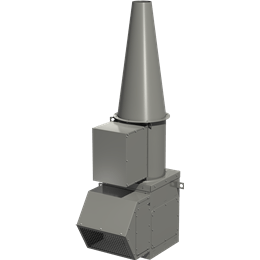

The Variable Geometry Nozzle (VGN) automatically adjusts to maintain the specified discharge velocity as airflow varies. This safely prevents re-entrainment in the make-up air unit. The VGN provides energy savings in reduced lab flow situations without introducing bypass air to maintain ANSI required outlet velocities.

VEKTOR-CS: The Vektor-CS safely maintains a constant discharge stack velocity at low volumes. This maintains ANSI guidelines for building design velocities regardless of laboratory exhaust airflow. The unit also reduces fan energy consumption on variable volume and demand-based ventilation systems. Drive components are out of the airstream. The motor is located at the roof deck level to the side of the common plenum. Vektor-CS is available in belt or direct drive and single to quadruple fan systems.

Certifications:

- UL/cUL Listed for Electrical (UL/cUL 705)

- AMCA licensed for FEI, Air & Sound Performance

- HCAI Seismic Certified

VEKTOR-MS: The Vektor-MS is an inline fan with a bifurcated housing to keep drive components out of the contaminated airstream. Its variable geometry nozzle (VGN) technology recognizes changes in airflow and static pressure in an occupied space. This causes the fan’s operation to adjust throughout the day based on demand. Vektor-MS is available in belt or direct drive systems and up to four fans per system.

Certifications:

- UL/cUL Listed for Electrical (UL/cUL 705)

- AMCA licensed for FEI, Air & Sound Performance

LABORATORY EXHAUST FANS CONTROLS:

It is important for controls on laboratory system to operate correctly, not only from a life safety aspect but also from energy savings and equipment life. Greenheck Vektor laboratory exhaust systems have a variety of levels in controls options. The system controls range from those that manage the all the components on the Vektor exhaust system to others that adjust discharge nozzles maintaining velocities with maximized plume heights and those that simply integrate and communicate with another control system operating on a building management system.

Controls logic and operable components are developed together as complete systems for seamless integration and coordination into lab applications.

VEKTOR SYSTEM CONTROL: The Vektor System Control (VSC) package offers a pre-engineered, stand-alone controller for laboratory exhaust fans. Components and sequences of operation easily integrate Greenheck Vektor exhaust fans into a variable or constant volume lab exhaust system.

Duct pressure modulation, fan speed, redundancy and fan rotation, isolation damper and bypass damper control are all handled by the Vektor System Control.

This control system is suitable for the following options and configurations:

- Vektor models H, MH, MD, CH, CD

- Single or dual fan configurations (maximum of two fans & isolation dampers)

- Exhaust system redundancy options of N+1, N-1 or none

- Single or dual bypass air damper applications

- BACnet® IP and BACnet MS/TP supported communication protocols

VARIABLE GEOMETRY NOZZLE: The Variable Geometry Nozzle (VGN) automatically adjusts to maintain the specified discharge velocity as lab airflow varies. This safely prevents re-entrainment in the make-up air unit and provides energy savings through lower fan speeds in reduced lab flow situations without introducing bypass air to maintain outlet velocities.

The VGN controller receives a signal from the factory provided pressure transducer and converts that signal into a fan flow. It then calculates the appropriate nozzle opening and sends a signal to the nozzle to adjust it to the proper size opening to maintain desired nozzle outlet velocity. Feedback signal provides BMS details as fan flow, nozzle position and a system alarm. The VGN controller does not signal operation of the fan speed, isolation or bypass dampers and it does not control duct pressure; those parameters are controlled by the BMS.

This control system is suitable for the following options and configurations:

- Vektor models MS, CS

- Controller for one or more fans (maximum of four)

- Adjusts individual fan outlet area to maintain discharge velocity

- Outlet velocity is a read/write parameter allowing on the fly adjustments based on outside parameters such as wind speed, chemical concentration levels or laboratory air flows.

- Communication with BMS through analog connections